SolidWorks: Scaling

In a program as complex as SolidWorks, there are going to be features that do not have nearly as many users as others. One such feature is scaling. Scaling is a tool that allows for the dimensions of a part to be changed all at once by a certain factor, instead of changing each individual one. Scaling can be used for adding clearance, accounting for thermal expansion, converting units, or if there are multiple instances of similar parts at different sizes.

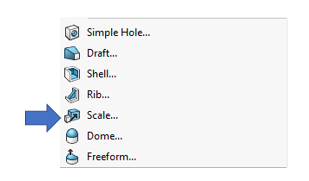

The Scale tool can be accessed by clicking Insert, then Features, then Scale, the icon shown in Figure 1.

Figure 1: Scale Feature Icon

Once the Scale feature has been selected, there are three choices to be made about how the scaling should be done: Scale about, Uniform scaling, and the scale. This is shown below in Figure 2.

Figure 2: Scale Property Manager

The first option, Scale about, determines the location the scale will use as the starting point. The scale is applied to both directions on each axis. When choosing where to scale about, there are three options: Centroid, Coordinate System, and Origin. These options can be seen by selecting the drop-down arrow, as shown in Figure 3 below.

Figure 3: Scale About Options

Scaling about the centroid makes the dimensions of the part larger or smaller in the X, Y, and Z direction, uniformly, about the center of the part. This is useful if there is no desire to know the location of the part after the scale has been completed.

Scaling about the origin changes the dimensions of the part using the origin as the starting place, which is useful if the location of the part after the scale feature needs to be known. This could be used in a situation where the origin of the scaled part is mated in an assembly to another part.

Scaling about a coordinate system is the same as scaling about the origin, but it is scaled around a custom coordinate system created by the user.

This choice will depend on whether the location of the part matters after the scale feature has been added.

The next option, Scale Uniformly, is either checked or unchecked. When unchecked, this allows the part to be scaled at different rates in the X, Y, and Z direction. This can be helpful if the part needs to be made taller, but not wider or deeper. This could be used in a situation when there are multiple uses of the same part, just at different sizes, like a support or dowel rod. If there are three supports, and the only difference is the length, then create one and scale it to the other sizes, then save as a separate part file. This can save a lot of time, as only one model needs to be created, and then two features can be added. This menu is shown below in Figure 4.

Figure 4: Expanded Menu

The scale is the number to be multiplied by the original dimension. If the part needs to be twice as large, then the scale would be 2. The scale can be any number between 0 and 10000000000.

Once those have been selected, click the green checkmark to complete the scale.

Scaling is a feature that is not used very often, however, there are uses for it. Two such uses are considering clearances and the thermal expansion of parts.

When designing, the parts are usually created to the perfect scale, but this is not always applicable to the real world. In order to take thermal expansion into account, first determine the amount of expansion that will occur. Next, take the inner part that will experience the expansion, and insert it into the outer shell part. Note that this must be done in the outer shell part file, as scaling does not work in assemblies. Scale the inner part to the correct size, and when given the option, do not merge entities. Finally, select the “combine” feature, which will remove the inner part and create the necessary cuts to add the clearance to the outer shell part.

One of the drawbacks of the scale feature is that it cannot be used in an assembly, only on parts. If an assembly needs to be scaled, the best way, although tedious, is to scale each part individually. Although the Scaling feature is not used very often in some industries, it can be very helpful in the right situation.

Thanks for reading, for any inquiries or contracting services, please don't hesitate to reach out to us!