SolidWorks: Sheet Metal Advanced Features

Sheet metal is widely used across multiple industries. SolidWorks has a very powerful set of tools that allows you to create versatile sheet metal parts with ease. How well do you know these tools and how often do you use them? This blog will be reviewing some of the more advanced sheet metal features within SolidWorks. And by the time you are finished reading this blog, you can be a master at creating sheet metal parts!

Tab and Slot

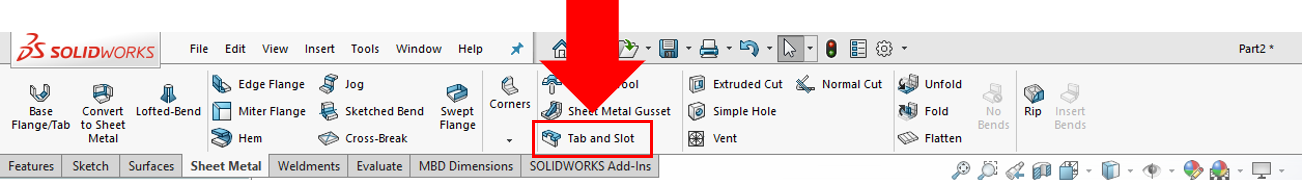

Generally, when you are welding two pieces of sheet metal together you need a fixture to hold them in place. This feature allows you to create tab and slot features between two sheet metal bodies. Tab and slot features are important on sheet metal parts as they allow the pieces to easily align and hold in place during manufacturing or installment. To see where the tab and slot command is located within SolidWorks see Figure 1 below.

Figure 1: Tab and slot feature location

To use the tab and slot feature you must have two separate sheet metal bodies. These two separate bodies must connect at one face, this connecting point is where the tab and slots will be inserted. See Figure 2 below for an example.

Figure 2: Tab and slot multiple body example

Once you have your two bodies set up you are ready to add tabs and slots! Click on the tab and slot command to open the feature manager. The first selection box will be asking for an edge, this will be the connection point between the two bodies. The next selection box will be asking for a face to be the slot face, this will be the face on the back of the connection point. In the case of my example image above, it would be the back of body 1. After a face is selected you will see a preview of the tab and slots. From here, you can adjust the number of tab/slots, the distance between instances, edge finish on tabs and more. When you are ready just hit the green check to create your tab and slot feature! See an example of the tab and slot feature manager below in Figure 3.

Figure 3: Tab and slot feature manager example

Swept Flange

The swept flange feature is a powerful command that allows you to make a flange with multiple bends in just one feature. This tool is great for saving time and keeping your feature tree short. This command works like other sweep commands and requires a profile sketch and a path sketch. To see where the swept flange command is located within SolidWorks see Figure 4 below.

Figure 4: Swept flange command location

Since this command will be creating a flange, your profile and path sketches should be on an edge of your sheet metal part. Take a look at my example below in Figure 5 that shows my multi bend profile sketch and my path sketch along the side of the sheet metal part. The profile sketch will be converted from a single line into a profile based off the sheet metal properties that are set up for the part (thickness, bend radius, K factor).

Figure 5: Swept flange sketch example

Once you have your desired sketches set up you are ready to create a swept flange! Select the swept flange command to open the feature manager. Similar to other swept feature managers, it will ask you to select the profile sketch that you would like to sweep and the path sketch to direct the sweep. Select your two sketches accordingly and click the green check mark! Within the feature manager you can further adjust the flange position, offset of the flange, custom bend allowance and relief type. Check out Figure 6 below for an example of the swept feature manager.

Figure 6: Example of swept flange feature manager

Venting

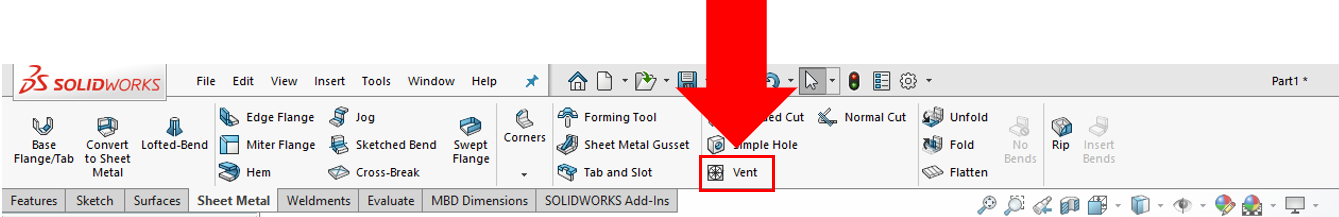

Often sheet metal components are used as covers or guarding in operations. Covers and guarding need to allow for sufficient airflow in order to keep operations running smoothly and avoid damaging components. SolidWorks offers a powerful venting feature that allows you to take simple sketches and create venting geometry with ease. To see where the venting feature is located within SolidWorks see Figure 7 below.

Figure 7: Venting feature location

The vent feature allows you to use simply sketch geometry to create complex vents in sheet metal parts. In order to use this feature you must first have a sheet metal body you would like to add a vent to. Once you have a sheet metal body, select which face you would like to have a vent on and start a sketch on that face. As you can see in my example below in Figure 8, I am going to be adding a circular vent with ribs to my sheet metal part. I have created a circular sketch with lines equally spaced around the center point. This is all the sketch geometry that I will need to create my vent.

Figure 8: Vent sketch example

After you have completed your sketch it is ready to create the vent! Select the vent feature to open the feature manager. The first selection box will ask you for the boundary of your vent, this will be the outer edge of your sketch. After selecting the boundary, you can select ribs from within the sketch, for my example I will choose the lines that are inside my circular sketch. After making your selections you can further adjust the boundary cutout, rib sizing, spars, and other boundaries to fill. Once you have made your selections and adjusted your settings you are ready to click the green check and create your vent! See Figure 9 below for an example of the venting feature manager.

Figure 9: Venting feature manager example

Conclusion

SolidWorks has a plethora of powerful tools and features that can make sheet metal design fast and easy. There are additional tools, features, and options that were not mentioned in this blog so if you have a blog topic that you would like us to write on feel free to contact us at sales@perceptioneng.com with your ideas!